The process decision screen is where you will set your average batch size, your setup time reduction expenditure, and how much you want to spend on preventative maintenance.

Maintenance is another factor in your Internal Quality as well maintained machines maintain their tolerances better and produce fewer defective products.

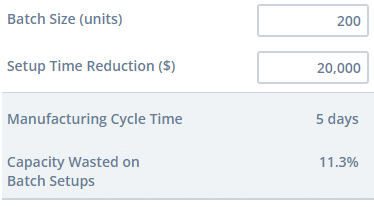

Batch Size

Batch size reflects the average quantity of bikes produced in a single manufacturing run.

Larger batch sizes reduce the number of setups and hence increase available capacity. However, this comes at the cost of increasing factory lead-time and potentially delivery times. Conversely, smaller batch sizes increase setup time but reduce delivery times. The predicted Manufacturing Cycle time for your factory will update as you save your new batch size decision.

Setup Time Reduction

Expenditure on setup time reduction goes into developing more efficient procedures for setting up manufacturing batches which reduces wastage (increasing effective capacity).

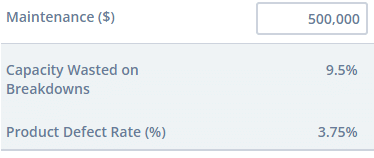

Preventative Maintenance

Preventative maintenance expenditure is the aggregate amount spent on servicing your plant machinery to reduce breakdowns and ensure maximum run time.

Preventative maintenance will also serve to reduce the number of product defects and so improves your Internal Quality. In addition, adequate maintenance also serves to maintain the resale value of your machinery if you ever need to sell capacity.

Note that as you increase your factory capacity, more expenditure is required to maintain the same level of maintenance.