The supply chain is a logistics system for converting raw materials into finished goods. As a manufacturer you must source raw materials from your suppliers to begin the production process.

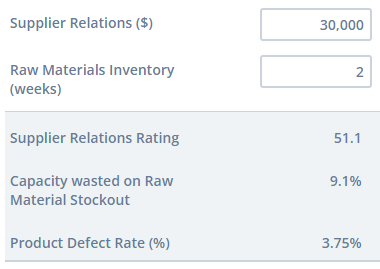

Under the Supply Chain menu you will be setting an amount spent on Supplier Relations and the amount of Raw Materials Inventory you would like to maintain:

Supplier Relations

Investment in supplier relations improves the delivery and quality of raw materials to your factory.

Expenditure is directed at improving contracts with suppliers, improving communication systems between suppliers and your factory, paying incentives to suppliers and expedient transport options.

Investing in supplier relations reduces raw material stockouts, therefore, reducing manufacturing stoppages. Note that the level of accumulated supplier relations deteriorates over time.

Good Supplier Relations is also another important factor in improving your Internal Quality as a consistent supply of higher quality raw materials will help to reduce product defects.

You can judge your progress by your Supplier Relations Rating (0-100).

Raw Materials Inventory

You will also decide the level of raw materials you require your factory to keep on hand at any given time. This is expressed in weeks of production.

Raw materials inventories provide a buffer to protect against current or unforeseen issues with suppliers to ensure there are sufficient materials to cover demand. Keep in mind that this does incur a warehousing cost and increased cashflow requirements to pay for the raw materials. So as your Supplier Relations Rating improves you could lower stocks of raw materials.