Henry Ford is known for his innovative assembly line and American-made cars . Like many, he wasn’t an overnight success. His early businesses failed and left him broke five times before he founded the now successful Ford Motor Company. As they say,

Remember that life’s greatest lessons are usually learned at the worst times and from the worst mistakes.

Over the years, we have noticed the three common mistakes that students make in MikesBikes Intro and we want you to learn from these and how you can resolve them.

Three of the most common mistakes in MikesBikes Intro are:

- Misunderstanding the Importance of Pricing Products Correctly

- Inaccurate Sales Forecasts

- Ineffective Spending in Operations

Mistake#1: Misunderstanding the Importance of Pricing Products Correctly

As Katherine Paine said, “The moment you make a mistake in pricing, you’re eating into your reputation or your profits.”

Price is usually a key determinant of demand and is the most critical component to maximizing your revenue. Therefore, carefully thinking about your Pricing strategy is important as this would have an impact on the demand for your products.

With a poor pricing strategy, you will be missing out on profits in every transaction that you make. View the “Market Summary Report”, in comparison to your competitors does your product have low Awareness, low Quality, low Distribution, or low Delivery (or all of the above)? If so you should price your product at the lower end of the market, if not and demand for your product is still average to high, then you can price your products at the higher end of the market. Keep in mind that extreme prices, high or low, will have a negative effect on Gross Margins.

There are several pricing methods, the most common of which are:

- Mark-up: Fixed margin on costs

- Target Return: Return/margin required by the company

- Perceived Value: What the consumer is willing to pay

- Going Rate: What is being charged in the market

These methods need to be in line with the overall marketing strategy. In addition, the retail price should be set by having regard for the price sensitivity of consumers and the prices of competitive products. This can be found in the Market Information Report (under the Key Reports menu).

Mistake# 2: Inaccurately Forecasting Sales

We have noticed two mistakes that students make in terms of forecasting sales:

- Excessive Closing Inventory

- Issues with Lost Sales due to lack of stock

Both of these scenarios are caused by inaccurately forecasting your firm’s sales for the year ahead. Ideally a firm would want to minimize this by correctly forecasting sales and adjusting your production based on this forecast (while also taking into account existing inventory levels).

There is a very helpful video available that demonstrates how to Forecast Sales within MikesBikes Introduction for new and existing products. Watch this here to learn how to Forecast your Sales accurately:

Mistake# 3: Ineffective Spending in Operations

Students often overspend or underspend in Operations and both have negative implications in their factory, its efficiency and the quality of their products.

There are three Operations decisions that you make in MikesBikes: Capacity, Efficiency and Quality.

Spending in these areas must be linked to your products and consumer preferences, some products require low Quality or high Delivery Time, whereas others revolve around Pricing and Advertising.

Capacity

Your Factory capacity is measured in Standard Capacity Units (SCU). The theoretical

capacity of a factory (in SCU) is calculated from the plant (machine) capacity and

the number and effectiveness of the workers.

For example, the standard Mountain bike requires 0.5 SCU to produce one

bike. If 500 SCU were available for production then the maximum output of

this design would be 500 SCU/0.5 SCU per unit = 1000 bikes (assuming zero idle

time and wastage).

Keep in mind that too much capacity relative to production/sales demand will result

in greater idle time (an inefficient use of resources causing higher average

manufacturing costs per bike). Also note that the maximum capacity you are able

to buy is set at the maximum amount of available cash you have for this year

before spending anything on any of your other budgets (decisions).

Capacity decisions should be made to accommodate your currently entered sales

forecasts and production decisions.

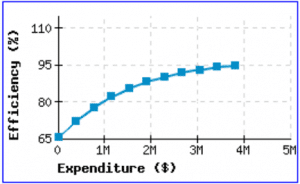

Efficiency

The Efficiency decision is used to enter the amount to be spent on reducing

wastage during production. Wastage relates to time spent on activities such as

setting up and maintenance of machines. In turn these activities act as a constraint

on production by absorbing a proportion (%) of the factory’s available capacity.

Note that increasing the size of your factory involves an increased Efficiency budget

to maintain your existing Efficiency level.

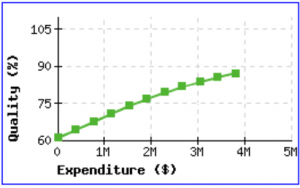

Quality

Quality refers to the satisfaction experienced by customers from a product and is an

important determinant of customer demand. It is measured in MikesBikes in terms

of the Quality Index which can be tracked on the Market Summary report.

Increasing the size of your factory involves an increased quality budget to maintain

your existing quality level. Before heavily investing in quality, consider your product

strategy as some segments are heavily sensitive to quality while others are not (if

you are planning to be a discount specialist then a large quality budget may be an

unnecessary expense, while if you are focusing on high end products they must be

produced to a high quality).

Conclusion

Every situation is unique within the simulation and these are only recommendations based on common mistakes we have found. As such there are no generalizations but this article will provide you with the tools to diagnose your unique situation and correct any problems you may be facing.

If you have any questions or would like to discuss anything further from what has been mentioned, please feel free to get in touch with us by clicking here.