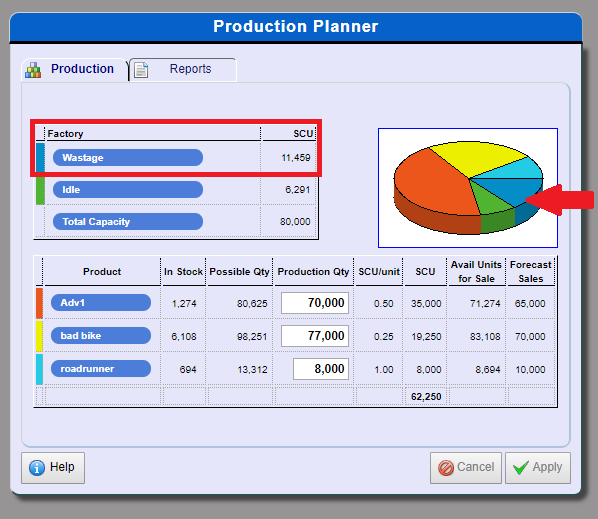

In MikesBikes Introduction, effective capacity will prove to be less than your plan capacity because of various Wastage factors such as:

- Rework

- Setup Time

- Raw Materials Stockout

- Machine Downtime

Wastage reduces your factory’s efficiency by using up time that could have been utilized to produce bikes. To improve or decrease Wastage, you will need to spend or economically increase your expenditure on Efficiency.

However, there are trade-offs on this. At a certain point, it can get more expensive to maintain a high factory Efficiency. So you will need to decide if it would be more economical to invest in expanding your factory (which can also be quite expensive and its value also depreciates over time) or you can choose to increase spending in Efficiency, which again gets costly at some point. The key is to find balance in between and see what works best with regards to what your firm is trying to achieve and what you believe to be a worthwhile investment.

As such, there is no “acceptable” percentage of wastage that you should be aiming for, as this is dependent on what your firm believes to be a more economical approach on balancing your factory’s efficiency.

Do you have a question suggestion for our next question of the week? Click here to fill out a form or email it through to help@smartsims.com.